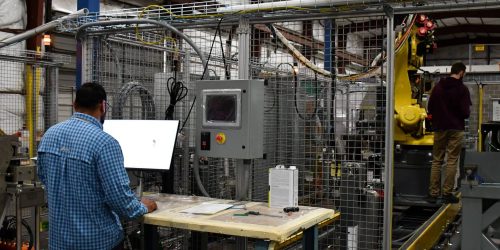

PLC programming powers industrial automation, enabling precise, efficient, and reliable machine operation. We develop and optimize control systems that seamlessly integrate and adapt to real-time processes, ensuring peak performance.

Custom Engineering and Design Services for Automated Systems

Custom Engineering and Design Services

IPS Custom Automation is much more than a manufacturing company, we are problem solvers. We pride ourselves on our ability to engineer custom solutions to help your business become more cost effective and efficient. Our engineers and technicians are experienced in working with various brands of programmable logic control systems for pneumatics, explosion-proof processing equipment, robotics, servo-positioning systems, and vision inspection systems.

Overview

IPS Custom Automation designs, manufactures, and installs custom automated equipment for Electronics, Automotive, Appliance, Defense, and Customer Product industries. Typical applications for these Custom Automation Systems include automated material handling, assembly, grease/glue applications, fastening and inspection. Our mechanical designs are developed in SolidWorks 3D and AutoCad 2D software, and our control designs are produced through PLC Programming and Robot Programming. Our automation experience combined with your expertise in the production of our specific products enables us to develop a machine or system that will increase product quality and lower annual production costs, thus increasing your profitability

Design Software Capabilites

We rely on SolidWorks to design, test, and refine custom automation solutions with unmatched accuracy. This powerful tool ensures seamless performance, efficiency, and innovation at every stage of development.

AutoCad 2D software offers increased design productivity and can lead to faster project approvals, giving various teams real-time access to the most current versions of a design and any adjustments.

Our Robotic Programming expertise ensures seamless automation, enabling robots to perform complex tasks with accuracy, efficiency, and adaptability. We develop and optimize custom programs that enhance performance, integration, and productivity across industries.

We utilize Rockwell Automation’s advanced control systems to power intelligent manufacturing processes. Their robust platforms enhance reliability, streamline integration, and support scalable automation tailored to our clients’ needs.

Allen Bradley hardware forms the backbone of our automation infrastructure. With industry-leading PLCs, HMIs, and motion control products, we build dependable, flexible systems designed for long-term performance and precision.

Our solutions are strengthened by Siemens’ innovative automation technology, delivering high-speed control, intuitive engineering, and seamless connectivity. Siemens empowers us to meet complex challenges with confidence and efficiency.

Beckhoff’s open automation systems allow us to push boundaries in flexibility and customization. With PC-based control and EtherCAT communication, we engineer next-generation solutions that are modular, responsive, and future-ready.