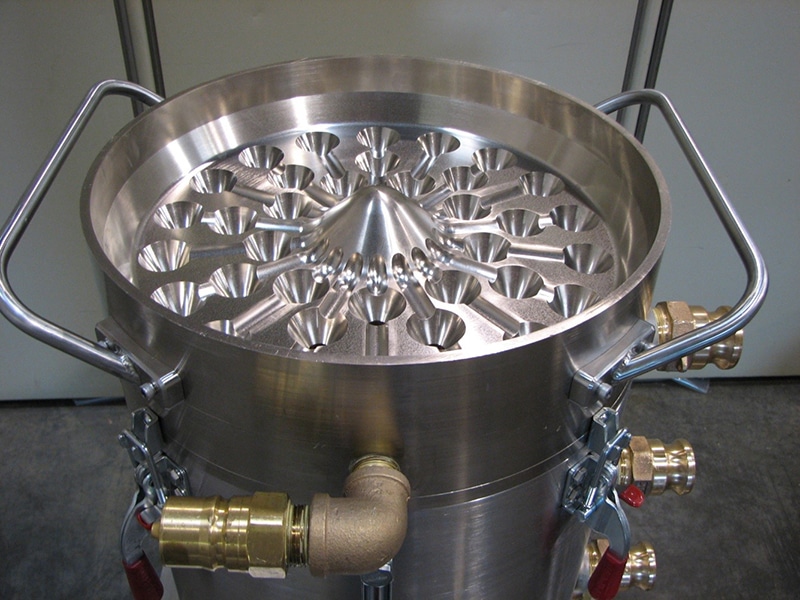

✔ Explosive Pouring Fixture – U.S. Army – IPS developed a steam-heated, cone-based fixture to evenly pour molten explosives into circular rows of Burster Tubes. The design was patented by the U.S. Army with IPS’s approval.

Designing and delivering mission-critical automation for the modern battlefield

OUR CAPABILITIES IN DEFENSE

From ruggedized automation systems to precision test equipment and fully integrated handling stations, IPS provides end-to-end engineering and manufacturing solutions that meet the unique needs of defense customers.

✔️ In-House Design & Fabrication

✔️ Military-Grade Automation

✔️ Experience with Army, DoD, and Defense Primes

✔️ Shortened Lead Times & High Reliability

Featured defense projects

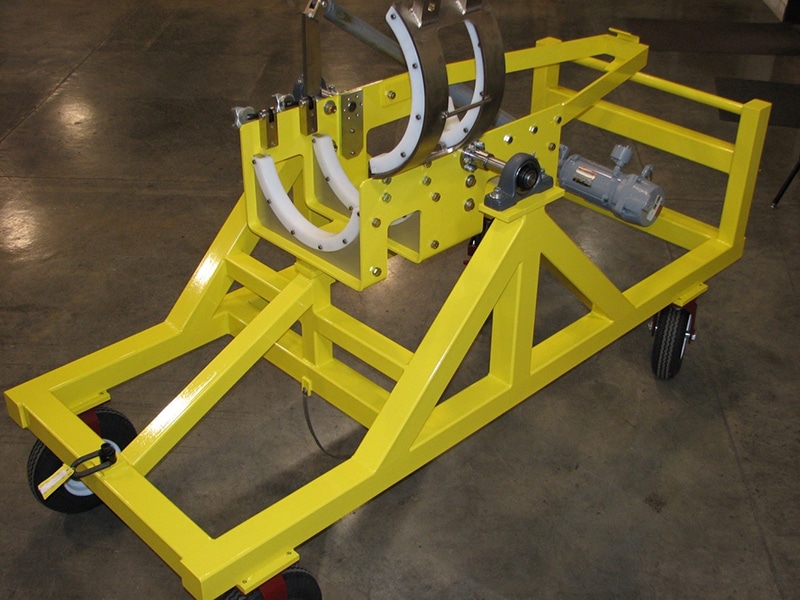

✔ Bomb Transport Carts – U.S. Army – IPS designed heavy-duty carts to safely transport and rotate 2,000 lb and 500 lb bombs, enabling single-operator handling from dock to production with full positional control.

✔ Burster Tube Facing Machine – U.S. Army – Custom machine allowing one operator to precisely machine both ends of Burster Tubes without impacting the inner diameter, using automated input and output conveyors.

✔ Explosion-Proof Monitoring System – U.S. Army – IPS built a custom control center with remote operation and explosion-proof CCTV to safely monitor and manage multiple machining bays processing explosive materials.

✔ Detonator Loader Retrofit – U.S. Army – IPS reverse-engineered a decades-old M55 Detonator Loader to run larger Booster Lead Cups, redesigning tooling, updating controls, and completing on-site installation.

✔ 10-Gallon Mixing Kettle – U.S. Army – IPS designed a heated, stainless steel kettle with custom mixing, vacuum, and safety features to prepare and dispense explosive mixtures with precision and control.

✔ Upgraded Hot Oil System – U.S. Army – IPS replaced and upgraded a multi-bay Hot Oil System with a custom Chromalox-based unit, new explosion-proof controls, piping, and safety interlocks.

✔ M18 Smoke Grenade Fuze Torque System – U.S. Army – IPS developed an automated system to inspect, place, and torque fuzes onto smoke grenades with precision, using vision systems and custom tooling.

✔ Spray Dryer System Installation – U.S. Army – IPS led the installation of a complex Spray Dryer System and auxiliary equipment, including explosion-proof cameras, ventilation upgrades, process utilities, and spill detection systems—ensuring safe, compliant operation in a hazardous environment.

✔ Video Inspection Machine – U.S. Army – IPS developed an automated system to inspect assembled mortars using laser sensors and high-resolution cameras, ensuring precise defect detection and traceable results through integrated data storage and HMI control.

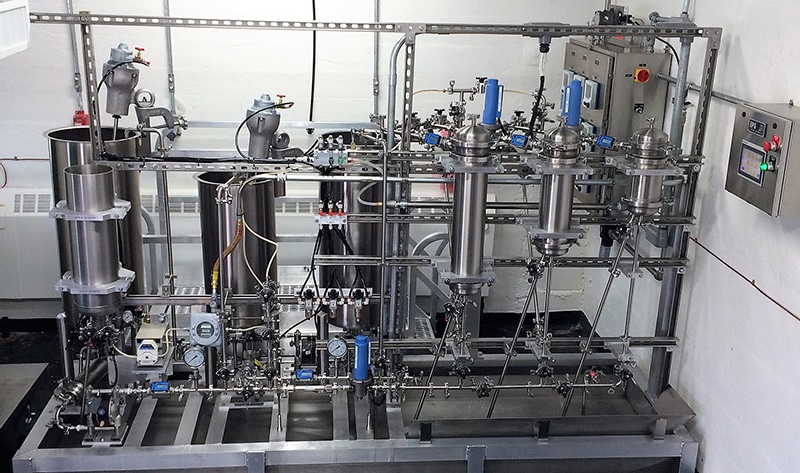

✔ Lab Scale Wastewater Treatment System – U.S. Army – IPS designed a flexible pilot system to test multiple filter media combinations for treating explosive-contaminated wastewater, featuring stainless steel construction, chemical dosing, and secondary containment for safe lab-scale evaluation.