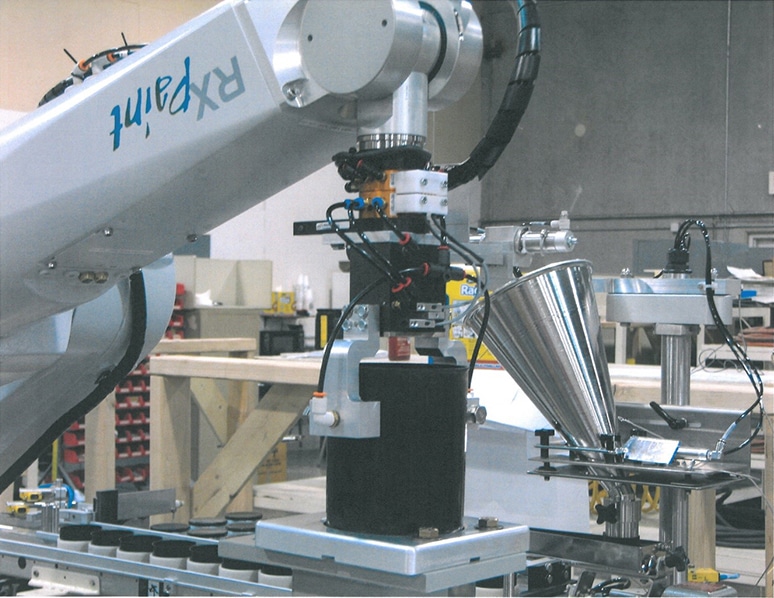

Robotic Powder Handling System

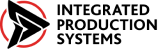

IPS designed, built and installed a robotic powder handling system to work in concert with a FillPro powder weighing system to dispense bulk quantities of either Lead Azide or Lead Styphnate into smaller containers with precisely measured amounts of powder. This automated system was needed to remove human operators from a potentially dangerous operation.

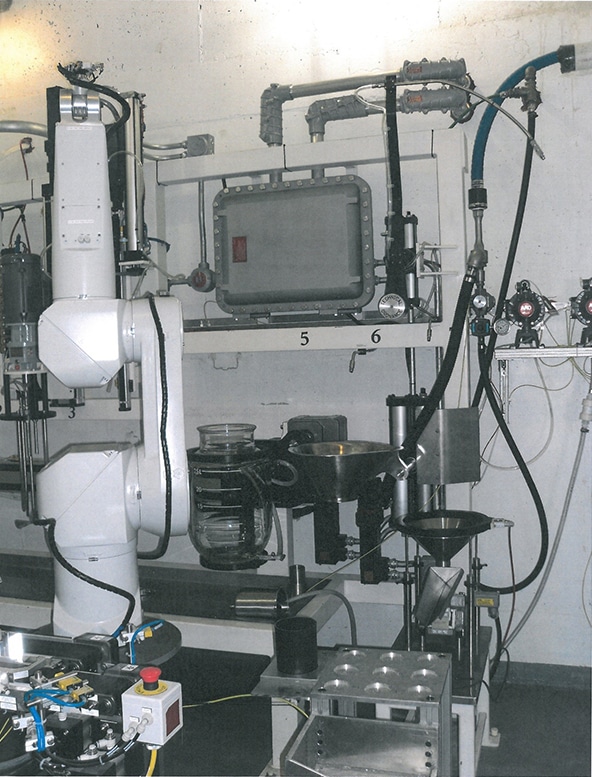

When the hopper of the powder weighing system reaches a low level, the robot picks up a quart velostat container from a supply conveyor system and slowly pours the powder into the stainless steel supply funnel of the powder weighing system. The robot pours the powder slowly onto the inside surface of the powder funnel to minimize dusting. A Staubli paint spraying robot was used for this application as the controls were already modified for use in a hazardous environment.

With the hopper resupplied, the robot automatically changes grippers and places small empty velostat containers onto an infeed conveyor where a precise amount of explosive powder is dispensed into them.